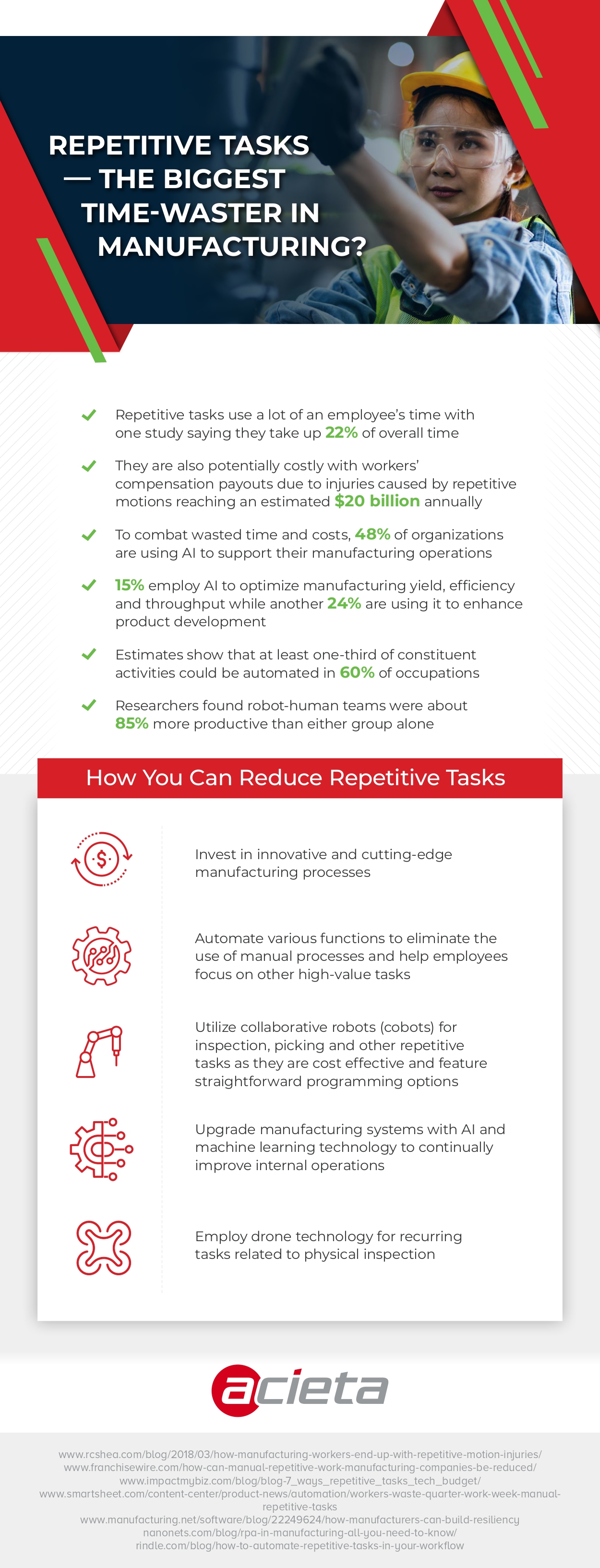

Monotonous responsibilities not only render work tedious for employees but also exert adverse effects on both productivity and a company’s financial performance. Surveys indicate that over 40% of workers across various industries dedicate at least a quarter of their work week to manual, repetitive tasks. In the realm of manufacturing, these mundane activities frequently involve data collection and manual data input. Many view such undertakings as an ineffective use of employees’ time, especially given the remarkable automation software prevalent in today’s market.

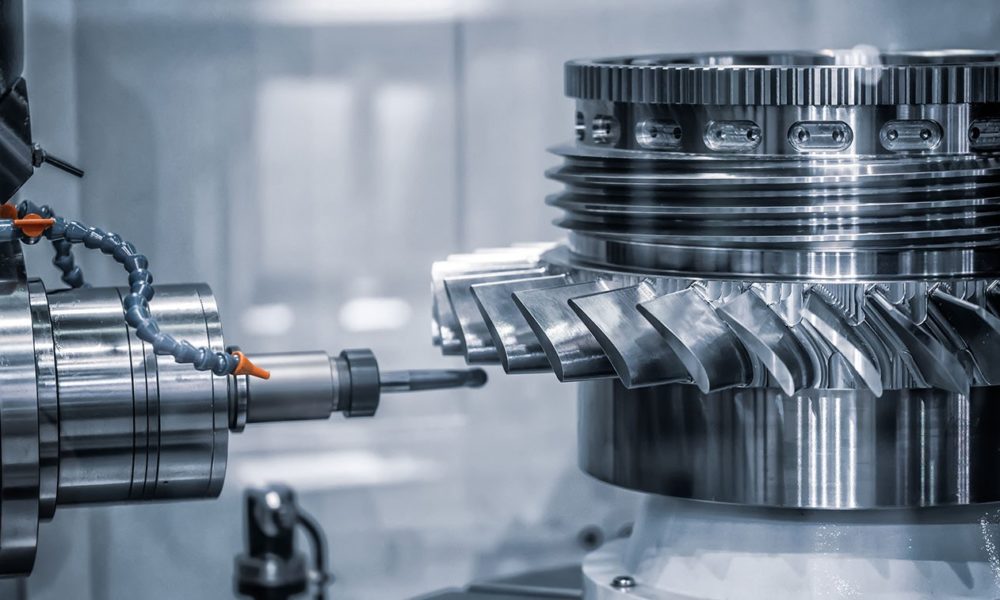

Automation presents just one avenue for mitigating repetitive and manual tasks. Numerous manufacturing entities are embracing state-of-the-art robotic technology. These programmed robots, or machines under robotic control, leverage artificial intelligence (AI) to augment an organization’s capabilities in assembly, material handling, and processing. When deployed in a foreseeable environment, robots can manage physically demanding or monotonous tasks that might otherwise adversely affect employees, whether through injury or diminished morale. The outcome is a substantial increase in productivity and a reduction in labor costs.

Here are several instances illustrating how organizations are leveraging technology to diminish, or even eradicate, repetitive tasks in the manufacturing sector.

Repetitive Tasks in Manufacturing from Acieta, a provider of robotic manufacturing for automobiles